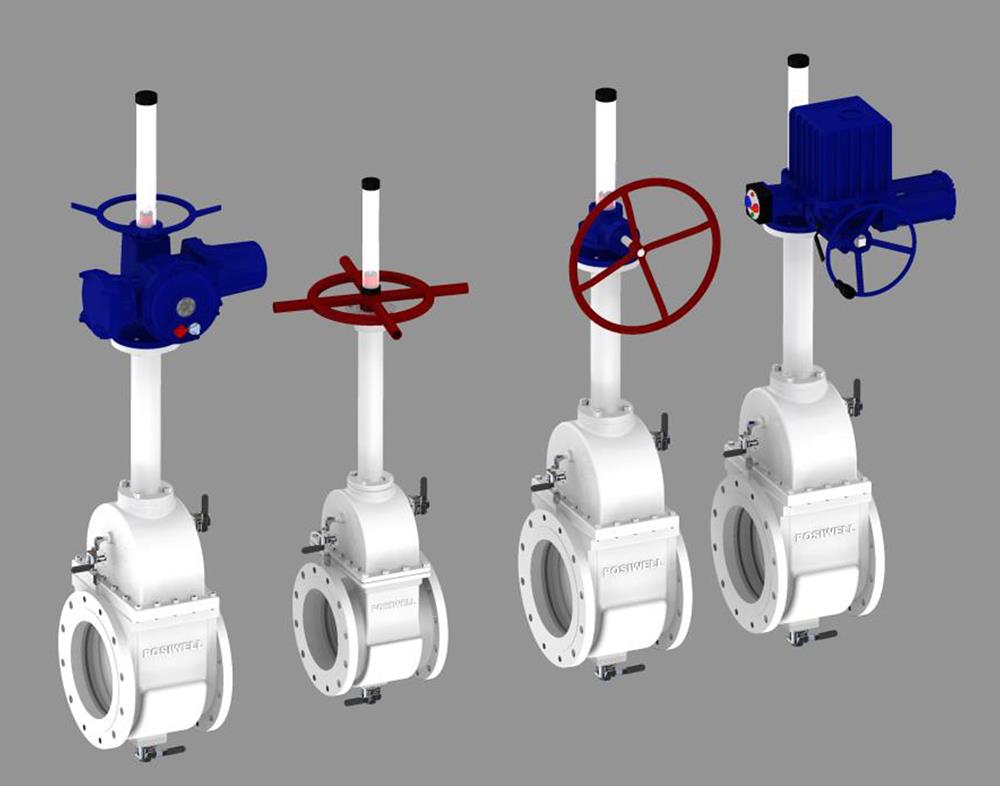

PosiWell® Double Block & Bleed (DBB) Gate Valves

PosiWell® Double Block & Bleed (DBB) Gate Valves

PosiWell Double Block & Bleed Gate Valves have been designed by engineers with over three decades of experience at the forefront of valve service,

repair, modifications and automation and a deep understanding of the root causes of DB&B valve failures.

Applications include:

- Aviation terminals

- Oil and gas terminals

- Hydrant isolation

- Tank storage isolation

- Any application that requires zero leakage performance

Benefits:

- Full bore - MAX FLOW - increased flow rate vs plug valves

- Pipeline pigging / smart pigging compatible

- API 6D compliant - ISO14313 dd. Aug 2015 Valves for DBB and DIB

- Body and bonnet materials are zinc phosphate treated - NO electroless nickel plating. NO peeling, flaking or cracking.

- Primary seal is metal-to-metal tested to API 6FA (fire safe)

- Secondary seal RTFE / PTFE alternative

- Thermal relief - bonnet bleed - body drain - standard feature

- Stainless steel valves and piping

- Thermal relief valve drain can be installed either side of flange

- Low torque (use of smaller actuators)

- Face to face as per a standard gate valve (ANSI B16.10 RF Smoot Finish, 125-250AARH)

- Fugitive emission “TUV” tested and certified to EN-ISO 15848-1

- Can be installed in the horizontal or vertical plane

- Rising and non-rising stem configuration available

- CE & PED compliant

- 2” to 40” ANSI Class 150 - Class 300

- ANSI 600 plus other sizes - consult Soliflo

With corrosion and chemical additives being the main causes of failure within traditional DBB valve design, PosiWell DBB-DIB valves come standard fitted

with stainless steel trim and in-line replaceable Teflon seat.

In the event of a seat failure, inspection and replacement is a simple task.

Operating Principles: Rising Stem Valves

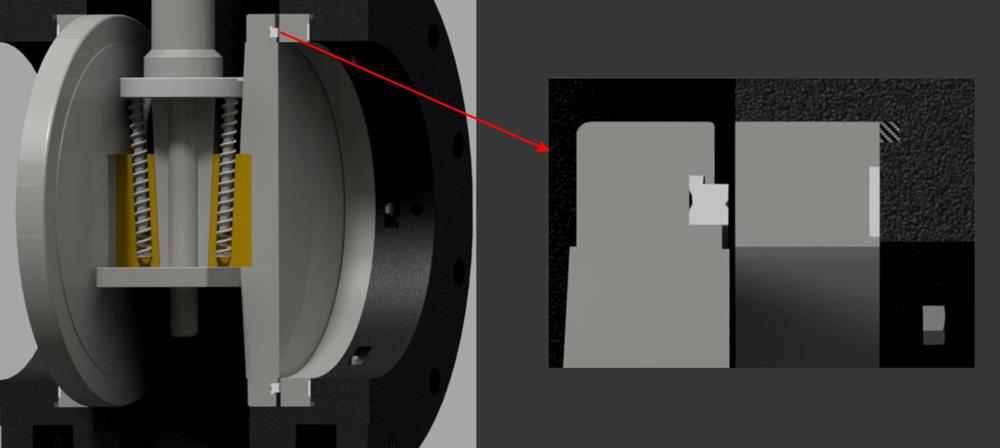

Figure 1: Valve in fully open position with discs fully retracted in bonnet ensures: full bore = maximum flow = pigable

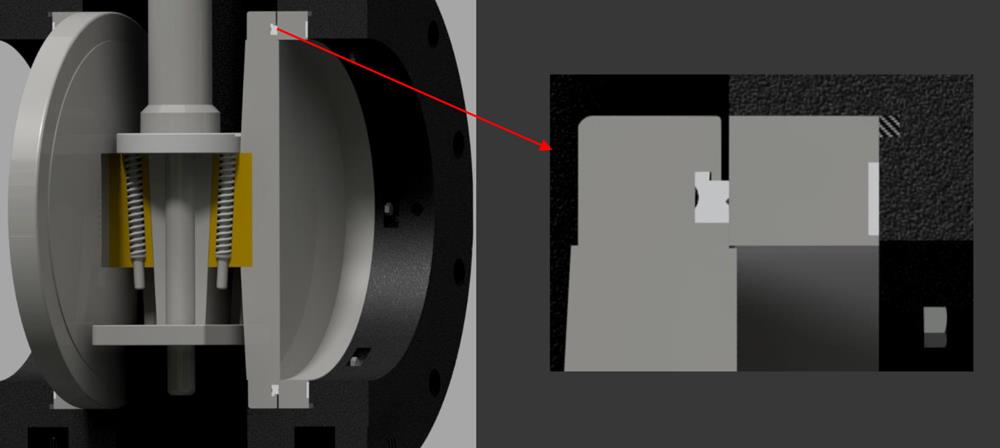

Figure 2: Valve in closed position, discs fully retracted and located on disc shoulder. Disc / seat clearance depending on valve size are 1.5 to 2.5mm.

Figure 3: Valve in fully closed position with discs fully expanded.

Sealing on metal/metal + resilient

Operating Principles: Non-Rising Stem Valves

PosiWell non-rising stem valves maintain all functionalities and zero leakage performance.

Figure 1: Operating principles same as for standard rising stem valves except stem travels internally in the yoke.

Figure 2: Valve in closed position with discs still retracted.

Figure 3: Discs expanded and compressing the seat.

Spring-Loaded Disc Design:

The PosiWell patented spring-loaded discs design ensures that seat tightness is maintained during thermal expansion and contraction and both the

discs are adequately retracted before they start their uplifting motion.

Valve in closed position, springs decompressed, discs located on disc shoulders and retracted from valve seats.

Springs are compressed, discs expanded sealing on soft seat and metal-to-metal seat achieving bubble tight shut-off to API 6D – DBB/DIB-1 standard.

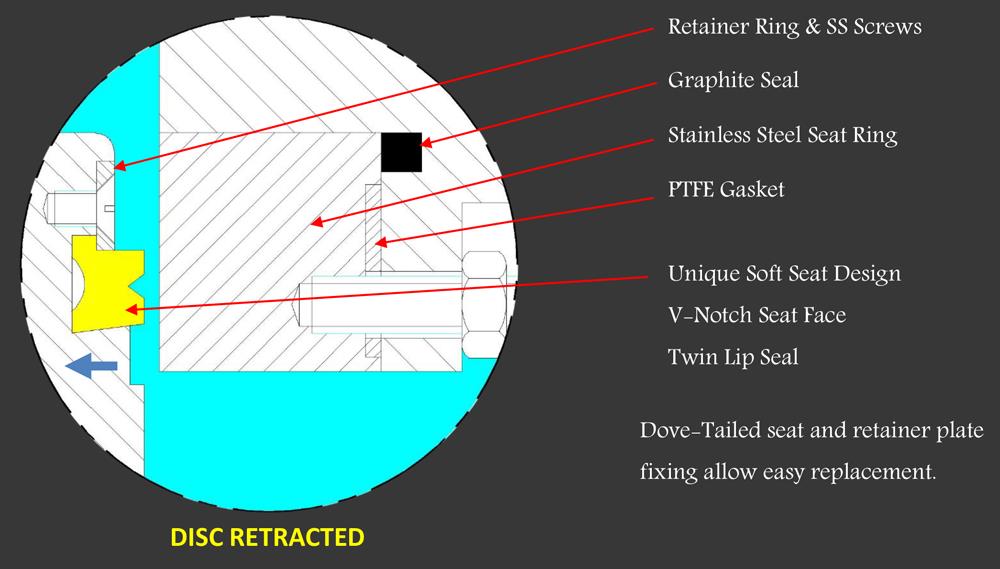

Seat-on-Disc Design:

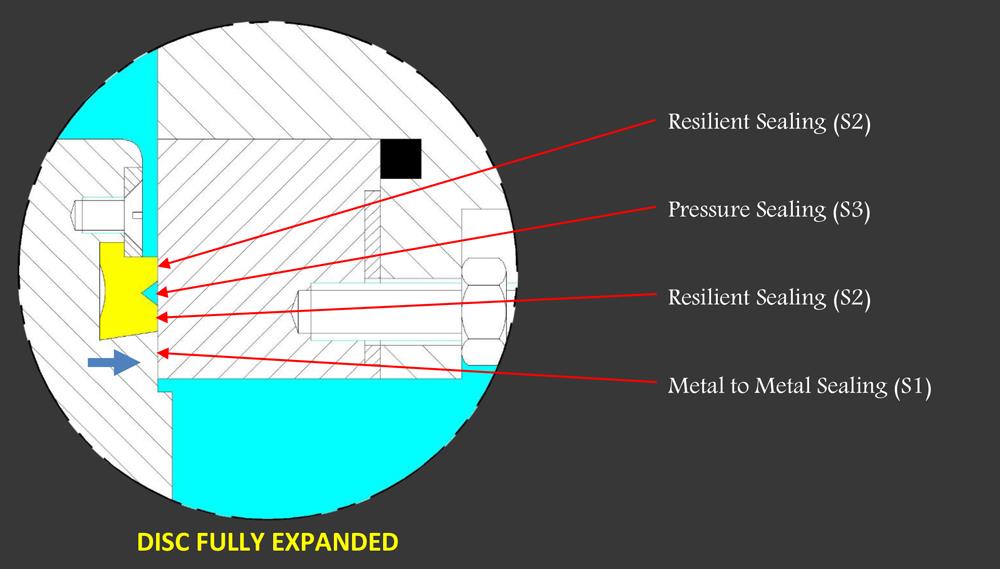

PosiWell DBB-IB valves are designed using a unique patented sealing concept (S1, S2 and S3).

-

Expanding discs’ primary seal will be metal-to-metal contact (S1).

-

For secondary seal, Soft V notch seat ring with twin lip sealing points (S2) and pressure sealing (S3), the concave back of the resilient

seat allows for the expansion and compression of the seat face.

-

Foreign debris will be flushed through by flow pressure before the expanding discs compress the resilient and metal seat.

-

Seat is designed for fast and easy in-situ replacement.

Disc retracted

Disc fully expanded